Electrical hazard are one of the most common—and most dangerous—risks in commercial buildings. From overloaded circuits to aging wiring, electrical hazard issues can develop quietly behind walls, inside panels, or around equipment long before anyone realizes something is wrong. When left unnoticed, these hazards can lead to costly downtime, equipment damage, fires, injuries, and even full-scale operational shutdowns.

The good news? Many electrical hazardrisks can be identified early with proactive inspections and an understanding of the warning signs. Below, we outline exactly how to spot electrical hazards in commercial facilities before they become serious problems, and how regular monitoring can protect your business, employees, and property.

1. Watch for Overloaded Circuits and Power Sources

Overloaded circuits are one of the most common causes of electrical failures in commercial buildings, especially in facilities with heavy equipment, office tech, refrigeration, or industrial machinery.

Warning signs of overloaded circuits:

- Frequently tripped breakers

- Dimming or flickering lights

- Warm or hot outlets, switches, or faceplates

- Buzzing sounds from panels or outlets

- Burned smells near electrical hazard areas

If your building regularly experiences breaker trips or voltage drops, it’s a strong indicator your circuits are carrying more load than they were designed to handle.

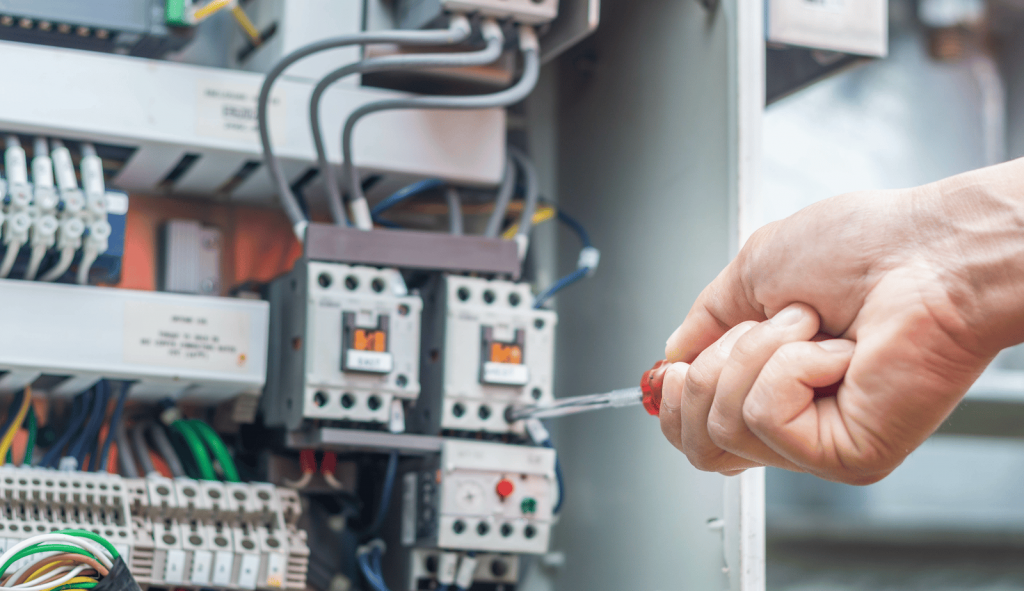

2. Inspect Electrical Hazard Panels for Heat, Corrosion, or Loose Connections

Electrical panels are the heart of your building’s power distribution. Issues inside a panel often signal developing hazards that must be addressed immediately.

Potential dangers include:

- Loose breakers or wiring

- Corroded terminals

- Overheating components

- Rust or moisture infiltration

- Outdated panels with insufficient capacity

Routine panel inspections by a licensed electrician can catch problems early, preventing shorts, arcing, or system-wide failures.

3. Look for Damaged, Exposed, or Aging Wiring

Wiring naturally degrades over time—especially in older buildings, high-traffic areas, or facilities with fluctuating temperatures.

Signs of wiring hazards:

- Frayed or cracked insulation

- Exposed copper

- Rodent damage

- Discoloration or scorch marks

- Loose conduit or hanging cables

Damaged wiring is a major fire risk and should be repaired immediately before equipment or employees are put in harm’s way.

4. Check for Overheating Electrical Equipment

Overheating is one of the earliest indicators of an electrical problem. Excessive heat often results from overloaded circuits, poor ventilation, worn-out components, or failing wiring.

Hot spots may occur on:

- Panels and sub-panels

- Breakers

- Switchgear

- Transformers

- Motors and equipment

- Outlets and junction boxes

Thermal imaging inspections (infrared scans) are an excellent way to identify heat issues before they turn into expensive repairs or fire hazards.

5. Monitor for Unusual Sounds or Smells

Your electrical system will often “tell” you when something is wrong.

Sounds that signal danger:

- Buzzing

- Crackling

- Clicking

- Humming that wasn’t there before

Smells that indicate trouble:

- Burning plastic

- Melting insulation

- Hot electronics odor

These symptoms suggest arcing, overheating, or imminent component failure—and should trigger immediate investigation.

6. Identify Extension Cord Misuse and Temporary Power Risks

Many commercial electrical hazards arise not from permanent wiring, but from improper temporary setups.

Common problems:

- Using extension cords as permanent power solutions

- Daisy-chaining multiple power strips

- Running cords under carpets or through doorways

- Plugging high-load equipment into lightweight cords

- Damaged or frayed cord insulation

Temporary solutions should never replace proper outlets, circuits, or dedicated wiring.

7. Evaluate Grounding and Bonding Systems

Proper grounding keeps your electrical system stable and safe. When grounding or bonding is compromised, even small faults can become dangerous.

Issues that affect grounding include:

- Loose connections

- Corroded grounding rods

- Improper bonding of equipment

- Unbalanced or unstable voltage

- Old or outdated grounding systems

Grounding problems often go unnoticed until equipment begins malfunctioning—or an electrical shock occurs.

8. Inspect GFCI and AFCI Devices Regularly

Ground-Fault Circuit Interrupters (GFCIs) and Arc-Fault Circuit Interrupters (AFCIs) are essential in areas with moisture, outdoor power, kitchens, shops, and high-risk zones.

Hazards occur when:

- GFCIs fail to trip properly

- AFCIs don’t activate during arcing

- Devices are outdated or missing

- Test/reset buttons no longer respond

Regular testing ensures your facility’s protective devices operate correctly.

9. Review Equipment Maintenance and Power Demands

As equipment ages or usage increases, electrical systems may become strained.

Warning signs include:

- Equipment running hotter than normal

- Frequent shutdowns

- Motor failures

- Voltage drops during startup

- Lights flickering when machines operate

A facility’s electrical system should always match its equipment’s power needs—not the other way around.

10. Schedule Regular Professional Electrical Inspections

Even with vigilant monitoring, many electrical hazards remain hidden until evaluated by a licensed commercial electrician.

Professional inspections can detect:

- Faulty breakers

- Underground wiring damage

- Panel overloads

- Hidden moisture exposure

- Thermal irregularities

- Code compliance issues

- Early-stage equipment failures

Routine inspections are the most effective way to prevent dangerous and costly electrical problems.

Conclusion: Prevent Problems Before They Happen

Identifying electrical hazards early isn’t just good practice—it protects your business from downtime, equipment damage, regulatory penalties, and safety risks. By watching for warning signs, maintaining equipment, and scheduling regular inspections, commercial facilities can ensure reliable, safe, and efficient electrical performance year-round.

A proactive approach today means fewer emergency repairs, lower costs, and better protection for your people and property.